Advertisement

If you have a new account but are having problems posting or verifying your account, please email us on hello@boards.ie for help. Thanks :)

Hello all! Please ensure that you are posting a new thread or question in the appropriate forum. The Feedback forum is overwhelmed with questions that are having to be moved elsewhere. If you need help to verify your account contact hello@boards.ie

Hi there,

There is an issue with role permissions that is being worked on at the moment.

If you are having trouble with access or permissions on regional forums please post here to get access: https://www.boards.ie/discussion/2058365403/you-do-not-have-permission-for-that#latest

There is an issue with role permissions that is being worked on at the moment.

If you are having trouble with access or permissions on regional forums please post here to get access: https://www.boards.ie/discussion/2058365403/you-do-not-have-permission-for-that#latest

Solar Panel Installation

Comments

-

I finally got the solar fitted on Monday, so with 40 Thermomax HP400 tubes feeding a 300L cylinder with no heat dump here's how it looked today.

0

0 -

Bet you're glad you went for the data logging option. Just one bit not looking quite right which is around 13:30. If you used a lot of water, I would expect the bottom temp to fall as the tank fills up with cold water but I don't understand why the top temp should fall too unless you used nearly the full 300l of hot water. Maybe check how high up this top sensor actually is located.0

-

The top sensor is about 1/3 from the top of the tank, I might have to get another sensor and put it right up top. Just not sure how to add an extra sensor to the controller, haven't tackled the user manual yet. Must say its great to have hot water all the time.Well impressed to say the least.0

-

Cocoon, as someone who is considering solar for hot water in the future, could you perhaps give some details of your system and total cost involved, estimated payback etc? It would be much appreciated to help me make up my mind whether it would be a good investment or not.

You can PM them if you don't want to post money amounts publicly.0 -

Have just joined Boards.ie, I find all the solar Energy Posts quite interesting, I'm a little surprised that there is no/little mention of measuring the Solar Output,most controllers now have the facility to do this, whilst this will never be 100% accurate it, in my opinion, gives a far more objective view of Solar Output and once set up is very useful for monitoring one's output over long periods. I would be very interested in any replies from anyone who is using this.

I installed a 2 (flat plate)panel DHW Solar System last year, completed on the 18/8/2011.

I removed the 40 year old cylinder and installed the new cylinder and reconnected all the boiler coil plumbing including a new motorized valve. I then got my local SEAI Approved plumber to install the two panels and install the solar pipework + associated controller and wiring. Total cost after Solar & BER Grants of €880 was €2706.

Due to Hot Press restrictions I installed a 150 Ltr Coppervented cylinder with twin coils, one is the oil fired boiler coil, the other consists of 3 micro bore (10 MM) coils, 1.0 M2 heating surface, connected inparallel and fitted in the bottom of the cylinder. A single 11 ins ElectricImmersion which I removed from my 40 year old cylinder is refitted in the top of the cylinder and can heat 30 ltrs of water.

The Solar Controller has 2 relay outputs, one starts/stops the solar circ. Pump and I have set the Delta T to 7C “On” and 3C “Off”. Thesecond relay operates a motorized valve fitted to the boiler coil, I have thisnormally programmed to be enabled betweem 1530 and 2330 hrs each day, I have itset at 50C “Shutoff” with a 5C hysteresis, ie it reopens the motorized valve at45C. During this summer I set the “Shutoff” to 20C to stop unnecessary usage of electricity, albeit only 9 watts/hr.

This (fairly basic) controller has a facility to measure thesolar output in KWh, both daily, which resets at midnight and the accumulated KWh. I installed an additional temperature(PT1000) probe in the coil return leg. The harvested output is measured bymultiplying the Flow Rate (inputted manually) By the temperature difference between the collector temperature and the return leg temperature and convertsthis to KWh. If the circ pump variable speed option is chosen then a flowmeter would have to be fitted.

The inputted Flow Rate is vital in achieving any sort ofreasonable accurate energy measurement.

I set up mine as follows: Ensured both Boiler Coil and ElectricImmersion “Off”. Ensured NO hot water was drawn off during the setting upperiod. I initially set the flow rate at the indicated “Flow Tube” rate of 4.0ltrs/min, (the circ pump runs at itslowest setting.) When the storetemperature and the top of cylinder temperature are the same, write down theindicated daily KWh (this updates every0.01 Kwh) at regular intervals (say every 20 minutes), write down the store+topof cylinder temperatures (which should be the same) ........when the cylinderhas reached a reasonably high temperature, say 60C write down the finalreadings. You then do a few calcs......I reckon the solar coil(s) heat a totalof 140 ltrs on my cylinder as they are a few cms off the bottom of thetank. Now multiply 140 X (the differencein readings for any given time period) and divide by 860 and compare this withthe difference in the indicated dailyKwh reading(s) for the same time period. I did these tests on a number ofdifferent days and found “on average” that the indicated daily KWh readingswere 70% of the calculated readings, I then manually changed the inputted flowrate from 4.0 ltrs/min to 2.8 ltrs/min, (2.8/4.0 = 70%).The above gives apretty good feel for the performance of the panels, I have done regular spotchecks and I have always found the readings are within the range of plus orminus 7% and are quite often “spot on”.

In the period 17/9/11 to the 17/9/12, my system has produced 864 Kwh from Roches Point Solar Radiation of 899 KWh.Based on an absorber area of 3.84 M2 this gives a panel output of, 864/3.84, 225.0 Kwh/M2/Annum. The Panel Manufacturers T-sol calculationis 273 Kwh/M2/Annum but this is based on a solarradiation of 1074 Kwh/M2/Annum

Whilst the above may seem to be a low output, I would sayits pretty representative of most Flat Plates over that same period in which the solar radiation at 899 KWh was less than 90% of the “normal”. I get mySolar Radiation numbers from “yesterdays weather” in met.ie......just multipythe number (which is in joules/cm2) By 0.00277777*, this converts joules/cm2 toKWh/M2. One can also get a rolling 7 day period in the above, under“agricultural data”.

The MAIN reason I choose FlatPlates is that the stagnation temperature is very low compared to EvacuatedTubes, I deliberately stagnated mine on a number of occasions and the highestpanel temperature reached was 110C, a friend of mine who has Evacuated Tubes afew miles away reached 245C at the same times that mine only reached 110C. Iprobably would have gone for the tubes if I had had room for a heat dump. 245Cis not good for any system, for example the solar circ pump seal is normally onlydesigned for water/glycol temperatures of 110C.

I use approx 110 ltrs/day of hot water with only 20 to 30ltrs/day over Saturday and Sunday. I have my Max Cylinder temperature set at80C, the mamimum cylinder temperature that I’ve seen even on a quite sunny weekend day with practically no usage was 76.5C. I have the CollectorProtection Temperature set at 105C (this has a non settable hysteresis of 10C),in other words the solar circ pump is disabled at 105C and enabled at 95C. The panels havenever stagnated since installation.

Finally, I’ve configured a few pretty sophisticated SolarControllers for friends of mine which use the difference between the collectoroutlet temperature and the STORE temperature for their KWh harvesting calculations,I have found this calculation to be far more inaccurate than using the returnleg temperature above.0 -

The top sensor is about 1/3 from the top of the tank, I might have to get another sensor and put it right up top. Just not sure how to add an extra sensor to the controller, haven't tackled the user manual yet. Must say its great to have hot water all the time.Well impressed to say the least.

To add extra sensors, you simply wire them up to the spare terminals on the wiring block. However, the sensor / display for the top of the tank has no effect on anything running in your system - it's purely a display item. Therefore, if there is a port in the tank higher up than the current one used, you can happily move the sensor. I middle sensor would only be used if you re-configure your system for top loading. If you add other sensors, you will only see the temps when analysing the data with the software. There is no way to view other temps via the panel.could you perhaps give some details of your system and total cost involved, estimated payback etc? It would be much appreciated to help me make up my mind whether it would be a good investment or not.

The SEI calculator tells me that my system should pay back in 10 years and I can certainly say that I feel that for me, it will pay for itself slightly quicker. Of course, if energy prices rise further, payback will of course be quicker still. My gas bill was annualizing out at around €1,350 and is now just under €900. A Kingspan 30 Tube 300L system may knock you back circa €5k. You'll have to shop around with installers.

No matter what system you buy, ensure it has Data Logging capability.John T Carroll wrote: »I'm a little surprised that there is no/little mention of measuring the Solar Output

Thanks for the challenge. I've now added my current and cumulative kWH to my COSM data feed at https://cosm.com/feeds/71436. The cumulative kWH is only since I turned on the function on 05/09/2012 whereas my system is installed since Jan 2010.0 -

I thought I'd climb up on the roof today and see how the tubes look up close.

So far I have to say we are impressed with the results and today being a sunny September afternoon we started out with 34-37 degrees in the tank and ended up with 57 degrees top and bottom all 300L.0 -

Hi Championc, I have posted the following as a quick reply but I didnt include a quote.

I have just spent an fascinating hour or so looking at the info on your live link.

If you have no objection, you might please answer a few queries.....

1. Did you draw off any hot water between periods 09 27 and 15 31 hrs today, Sat 22/9/12 ?

2. Do you know or can you ascertain where the buffer bottom probe is positioned in relationship to the solar coil? ie is it positioned just above the coil top or 2/3 the way up or whatever.

3. You refer to your system as "Thermomax HP300 System" I am familiar with the HP100 30 & the HP200 30 but

not with this system, any info would be much appreciated.

I downloaded the Steca TR0603mc Controller "Manual" and had a good look through it. The top Loading Function is referred to as the "Quick Charge". Even though it doesnt explain how it works, I would say that when enabled it raises the normal Delta T between the Collector Top and the Store temperature from its normal of say 8C (default setting) to

a much higher Delta T of say 16C (if solar radiation is strong enough)......it simply slows down the pump to achieve this. Now because the hotter the water is around the heating coil; its less dense and will rise faster through the body of water above it and will retain and then release more heat in the middle and top portions of the buffer tank where you want it initially, thats my story anyhow!

Hope this is the proper place to ask these questions, if not please tell me.

Thanks again....John0 -

I just want to add Friday and Saturdays data for those who may be interested in

the results comparing 40 tubes feeding 300L and Championc using 30 tubes feeding 180L. It should be interesting to compare data maybe Championc could post up the same two days data.

Friday 21/09/2012

Saturday 22/09/1012 0

0 -

Advertisement

-

0

0 -

John T Carroll wrote: »1. Did you draw off any hot water between periods 09 27 and 15 31 hrs today, Sat 22/9/12 ?

What make you think I used any hot water ? I am now looking at a 1 day graph. From 09:29 to 10:24, the temp fell due to now sun to heat the water but from 10:24 onwards, the temperature continued to rise. However, from 10:44 to 15:44, the system was Top LoadingJohn T Carroll wrote: »2. Do you know or can you ascertain where the buffer bottom probe is positioned in relationship to the solar coil? ie is it positioned just above the coil top or 2/3 the way up or whatever.

From memory, it's right beside the coil.John T Carroll wrote: »3. You refer to your system as "Thermomax HP300 System" I am familiar with the HP100 30 & the HP200 30 but

not with this system, any info would be much appreciated.

Ah, you might be right. I think it's a HP200 30John T Carroll wrote: »I downloaded the Steca TR0603mc Controller "Manual" and had a good look through it. The top Loading Function is referred to as the "Quick Charge". Even though it doesnt explain how it works, I would say that when enabled it raises the normal Delta T between the Collector Top and the Store temperature from its normal of say 8C (default setting) to a much higher Delta T of say 16C (if solar radiation is strong enough)......it simply slows down the pump to achieve this. Now because the hotter the water is around the heating coil; its less dense and will rise faster through the body of water above it and will retain and then release more heat in the middle and top portions of the buffer tank where you want it initially, thats my story anyhow!

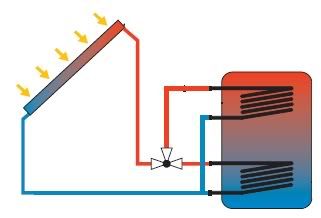

I think you are more or less correct. If the system sees strong system output, it will feed the whole tank, otherwise it will just heat the top section. So my buffer has two coils, fed from the single solar tube array, with a diverter valve controlled by the Solar Controller, like this 0

0 -

Thanks for that info Championc, I couldnt figure out why the buffer bottom (Store) temperature wasnt rising, so top loading means exactly as it states,ie two coils with a diverter valve......the quick charge is an attempt to achieve this in a generic way....I wouldnt say it would be very successful, you have the right set up there especially since you havn't auxiliary heating in the buffer tank.

I knew a few people with the HP200 30 like you and they are very happy....they both use a bit of logic to use the boiler coil in the hot water (buffer) cylinder as a heat dump, one is excellent as it is a high output coil with a very large heating (or cooling) surface,0 -

My original plan was to use it as a heat dump and connect to the rads circuit for the odd hour or two of chilly evenings in the summer, but it just wasn't worth doing.

So my aim now is to maximize Spring and Autumn and especially Winter sunshine. My target is always to get to 45 deg C and I have a decent chance if using my 30 tubes to now heat only 90 litres of water.0 -

My original plan was to use it as a heat dump and connect to the rads circuit for the odd hour or two of chilly evenings in the summer, but it just wasn't worth doing.

So my aim now is to maximize Spring and Autumn and especially Winter sunshine. My target is always to get to 45 deg C and I have a decent chance if using my 30 tubes to now heat only 90 litres of water.

I think i've finally figured out what system is in use......from the info from your trends it is probably System 5 (Zone Loading) see page 28 of thr Steca Manual. Basically if the Buffer Top Temperature is below 60C, the diverter valve is energised and the Solar System feeds the Top Coil, if the Buffer Top Temperature is above 60C then the appropriate Relay is denergised and the Solar System feeds the bottom coil in the traditional way. If Temperature Differential Loading is selected then with Top Loading the Solar circ pump will try and keep the collector temperature 8C above the Buffer Top, if Top Loading is OFF, then the pump speed will be controlled to try and keep the collector temperature 8C above the Buffer Bottom. The Quick Charge option, I would think, is not enabled.0 -

It is indeed System 5 and I was expecting it to work the way you described - only loading the bottom once the top reached 60 deg C but you can see from my data that this is not how it works in reality. I rang Steca in Germany and a really helpful guy started explaining stuff to me, speaking a few times about Delta T which was when he was losing me somewhat but basically it does as I described previously which is that it all depends on the strength of heat being produced and if the system sees plenty, it reckons the optimum use for it is to heat the whole buffer rather than just the top.0

-

Advertisement

-

It is indeed System 5 and I was expecting it to work the way you described - only loading the bottom once the top reached 60 deg C but you can see from my data that this is not how it works in reality. I rang Steca in Germany and a really helpful guy started explaining stuff to me, speaking a few times about Delta T which was when he was losing me somewhat but basically it does as I described previously which is that it all depends on the strength of heat being produced and if the system sees plenty, it reckons the optimum use for it is to heat the whole buffer rather than just the top.

I think I know what the German chap was saying.....basically any solar panel runs at higher efficiencies when the difference between the collector and the ambient temperature is lowest, lets take your system and some readings from Saturday. At 14:14:35 Top Loading ON, collector temp:61C,Top Buffer 56C,Mid Buffer 56C, Bott Buffer 43C. Now all this is correct BUT the temperature difference between the collector and the Top buffer is 5C, the solar circ pump switches off at a Delta T of 4C (default setting), again because the Delta T remained a little above 4C the Top Loading remained active until the Top Buffer reached 60/61C at 15:14:39.

If the Solar Radiation (cloud etc) had reduced during this period until the Delta T fell below 4C then I reckon that the Top Loading would be switched Off (otherwise the circ pump would stop) and the Bottom Coil would be loaded. One might say, so what?, but because the collector temperature would then be lower because the collector is now receiving water from a coil immersed in colder water then the efficiency of the system will increase and keep the Delta T from falling below 4C, it would probably switch back to Top Loading again if the sun came out and the Delta T increased to the switching level. I inputted the HP 200 30 data into a Spreadsheet that I cobbled together a few years ago and it tells me that if the solar radiation was 230 watts/M2 (cloudy conditions) with a collector temp of 59C and ambient of 15C then the efficiency will be 48%. If the collector temperature is reduced to 48C then the efficiency will be 60% so more heat will be produced and this will keep the Delta T from reaching the pump cut out at 4C.

Now I know the German chap seemed to say the sort of converse of this but he may not have explained it clearly. Anyway,one way or the other, we will monitor the trends closely and see exactly whats happening. Basically, if you have enough solar radiation, the Top Loading should stay ON until the Top buffer reaches 60C as it did yesterday.0 -

I finally got the solar fitted on Monday, so with 40 Thermomax HP400 tubes feeding a 300L cylinder with no heat dump here's how it looked today.

Hi Cocoon, Can you enable the cumulative KWh output as Championc is now doing?. It would be interesting to compare the three, ie 40 tubes feeding 300L, 30 tubes feeding 180L, and (mine) 2 Flat Plates feeding 150L.

Do you have auxiliary heating on your cylinder? and is it enabled?.

Thanks for the trends...John0 -

John T Carroll wrote: »Hi Cocoon, Can you enable the cumulative KWh output as Championc is now doing?. It would be interesting to compare the three, ie 40 tubes feeding 300L, 30 tubes feeding 180L, and (mine) 2 Flat Plates feeding 150L.

Do you have auxiliary heating on your cylinder? and is it enabled?.

Thanks for the trends...John

Hi Championc, "System 14" attached.....unable to PM.......JTC0 -

John T Carroll wrote: »Hi Cocoon, Can you enable the cumulative KWh output as Championc is now doing?. It would be interesting to compare the three, ie 40 tubes feeding 300L, 30 tubes feeding 180L, and (mine) 2 Flat Plates feeding 150L.

Do you have auxiliary heating on your cylinder? and is it enabled?.

Thanks for the trends...John

Hi John, I enabled the cumulative KWh since the 15th of Oct and its showing 80KWH since then. I do have auxiliary heating but its only used for around 1/2 hour on mornings when the top of the tank falls below 45 degrees on a dull day. The house is well insulated and the only necessary form of heating I use is a stand alone solid fuel stove on the chilly evenings.

Here is a copy of 03/11/12 if you want to compare values, I don't think the central heating was used that sunny morning. 0

0 -

Hi John, I enabled the cumulative KWh since the 15th of Oct and its showing 80KWH since then. I do have auxiliary heating but its only used for around 1/2 hour on mornings when the top of the tank falls below 45 degrees on a dull day. The house is well insulated and the only necessary form of heating I use is a stand alone solid fuel stove on the chilly evenings.

Here is a copy of 03/11/12 if you want to compare values, I don't think the central heating was used that sunny morning.

Thats very interesting Cocoon....my 2 X Flat plates (Solimpeks, Marvel CLS 2108) made 54 KWH for that period and assuming that both our harvested totals are reasonably accurate then your system made almost 50% more than mine which I would say is par for the course of Evac.Tube/Flat plate output.

Quentingaren made a very interesting point re the "cheap" Flasks..while they are not quite as good as the K.Span type, they are certainly very cheap to replace, a friend of mine who examines everything with a fine tooth comb is currently installing 60 of these with a 200 litre cylinder AND a heat dump (on my advise), it will be interesting to see how they perform, I will be commissioning it for him, it also includes a harvesting capability. Ecologics.ie have some very non partisan info on their website, its well worth reading. JTC0 -

Advertisement

-

Just checked up on my data and would seem I generated 51kWH. I've been messing about with my system over the past week (thanks John T.) and discovered that the Heat Quantity function stopped working but I'm fairly sure it's ready to start it's calculating again.0

-

Just checked up on my data and would seem I generated 51kWH. I've been messing about with my system over the past week (thanks John T.) and discovered that the Heat Quantity function stopped working but I'm fairly sure it's ready to start it's calculating again.

Please find attached excel file with some interesting numbers from info taken

yesterday Sat 17th.Nov. via your excellent Raspberry PI. JTC0 -

John T Carroll wrote: »Have just joined Boards.ie, I find all the solar Energy Posts quite interesting, I'm a little surprised that there is no/little mention of measuring the Solar Output,most controllers now have the facility to do this, whilst this will never be 100% accurate it, in my opinion, gives a far more objective view of Solar Output and once set up is very useful for monitoring one's output over long periods. I would be very interested in any replies from anyone who is using this.

I installed a 2 (flat plate)panel DHW Solar System last year, completed on the 18/8/2011.

I removed the 40 year old cylinder and installed the new cylinder and reconnected all the boiler coil plumbing including a new motorized valve. I then got my local SEAI Approved plumber to install the two panels and install the solar pipework + associated controller and wiring. Total cost after Solar & BER Grants of €880 was €2706.

Due to Hot Press restrictions I installed a 150 Ltr Coppervented cylinder with twin coils, one is the oil fired boiler coil, the other consists of 3 micro bore (10 MM) coils, 1.0 M2 heating surface, connected inparallel and fitted in the bottom of the cylinder. A single 11 ins ElectricImmersion which I removed from my 40 year old cylinder is refitted in the top of the cylinder and can heat 30 ltrs of water.

The Solar Controller has 2 relay outputs, one starts/stops the solar circ. Pump and I have set the Delta T to 7C “On” and 3C “Off”. Thesecond relay operates a motorized valve fitted to the boiler coil, I have thisnormally programmed to be enabled betweem 1530 and 2330 hrs each day, I have itset at 50C “Shutoff” with a 5C hysteresis, ie it reopens the motorized valve at45C. During this summer I set the “Shutoff” to 20C to stop unnecessary usage of electricity, albeit only 9 watts/hr.

This (fairly basic) controller has a facility to measure thesolar output in KWh, both daily, which resets at midnight and the accumulated KWh. I installed an additional temperature(PT1000) probe in the coil return leg. The harvested output is measured bymultiplying the Flow Rate (inputted manually) By the temperature difference between the collector temperature and the return leg temperature and convertsthis to KWh. If the circ pump variable speed option is chosen then a flowmeter would have to be fitted.

The inputted Flow Rate is vital in achieving any sort ofreasonable accurate energy measurement.

I set up mine as follows: Ensured both Boiler Coil and ElectricImmersion “Off”. Ensured NO hot water was drawn off during the setting upperiod. I initially set the flow rate at the indicated “Flow Tube” rate of 4.0ltrs/min, (the circ pump runs at itslowest setting.) When the storetemperature and the top of cylinder temperature are the same, write down theindicated daily KWh (this updates every0.01 Kwh) at regular intervals (say every 20 minutes), write down the store+topof cylinder temperatures (which should be the same) ........when the cylinderhas reached a reasonably high temperature, say 60C write down the finalreadings. You then do a few calcs......I reckon the solar coil(s) heat a totalof 140 ltrs on my cylinder as they are a few cms off the bottom of thetank. Now multiply 140 X (the differencein readings for any given time period) and divide by 860 and compare this withthe difference in the indicated dailyKwh reading(s) for the same time period. I did these tests on a number ofdifferent days and found “on average” that the indicated daily KWh readingswere 70% of the calculated readings, I then manually changed the inputted flowrate from 4.0 ltrs/min to 2.8 ltrs/min, (2.8/4.0 = 70%).The above gives apretty good feel for the performance of the panels, I have done regular spotchecks and I have always found the readings are within the range of plus orminus 7% and are quite often “spot on”.

In the period 17/9/11 to the 17/9/12, my system has produced 864 Kwh from Roches Point Solar Radiation of 899 KWh.Based on an absorber area of 3.84 M2 this gives a panel output of, 864/3.84, 225.0 Kwh/M2/Annum. The Panel Manufacturers T-sol calculationis 273 Kwh/M2/Annum but this is based on a solarradiation of 1074 Kwh/M2/Annum

Whilst the above may seem to be a low output, I would sayits pretty representative of most Flat Plates over that same period in which the solar radiation at 899 KWh was less than 90% of the “normal”. I get mySolar Radiation numbers from “yesterdays weather” in met.ie......just multipythe number (which is in joules/cm2) By 0.00277777*, this converts joules/cm2 toKWh/M2. One can also get a rolling 7 day period in the above, under“agricultural data”.

The MAIN reason I choose FlatPlates is that the stagnation temperature is very low compared to EvacuatedTubes, I deliberately stagnated mine on a number of occasions and the highestpanel temperature reached was 110C, a friend of mine who has Evacuated Tubes afew miles away reached 245C at the same times that mine only reached 110C. Iprobably would have gone for the tubes if I had had room for a heat dump. 245Cis not good for any system, for example the solar circ pump seal is normally onlydesigned for water/glycol temperatures of 110C.

I use approx 110 ltrs/day of hot water with only 20 to 30ltrs/day over Saturday and Sunday. I have my Max Cylinder temperature set at80C, the mamimum cylinder temperature that I’ve seen even on a quite sunny weekend day with practically no usage was 76.5C. I have the CollectorProtection Temperature set at 105C (this has a non settable hysteresis of 10C),in other words the solar circ pump is disabled at 105C and enabled at 95C. The panels havenever stagnated since installation.

Finally, I’ve configured a few pretty sophisticated SolarControllers for friends of mine which use the difference between the collectoroutlet temperature and the STORE temperature for their KWh harvesting calculations,I have found this calculation to be far more inaccurate than using the returnleg temperature above.

Have just completed 1 full calender year of running. (see excel attachment)

The Panel (2 X F.Plate) output was 918 Kwh from a Roches Point Solar radiation of 945 Kwh. This output equals 239 Kwh/M2 of panel. Inputting my details to the DEAP S.Sheet comes up with 270 Kwh/M2. I know there is a view out there that this should be 350/400 Kwh/M2 but I have never been of this persuasion, reasonably accurate measurement of the harvested output is really the only objective way of really knowing what your system is producing. A friend of mine (Cork) who has the "normal" setup of 3 F.Plates X 300 Litre Cylinder harvested 1336 Kwh, this gives an almost identical performance of, 1336/5.76, 232 Kwh/M2.There was no output from my panels for 37 days this year which just goes to show what a dismal summer we had even though it didnt have a huge effect on the Solar Radiation.

What did surprise me was that when I inputted my details into the DEAP S.Sheet and assuming an E.Tube array of the same Aperture Area (3.84 M2) that it only gave an output of 310 Kwh/M2 which is only 14.8% greater than the theoretical output of 270 Kwh/M2 for the F.Plate. The T-Sol gives a better but still poor, in my opinion, approx 25% better performance for the E.Tube(s). I would have expected at least 50% better performance but again, the only way to go is to measure it!.

So, finally, to answer the query "are you all pleased with your solar panels for hot water heating", my reply is yes, and even though pay back time is very long, it was the best €2706 that I've spent in a very long time, from a personal satisfaction point of view.

My roof pitch is 30/33 Deg. due South.

Happy New Year to All "on the Boards". JTC0 -

I thought I'd bring this thread back up seen as we have a bit of sunshine again.

I came home today to see that the panel had reached 135c, is this a problem as its only April and its over heating. Would 135c be considered stagnation that could damage the system or is it within normal parameters? 0

0 -

I thought I'd bring this thread back up seen as we have a bit of sunshine again.

I came home today to see that the panel had reached 135c, is this a problem as its only April and its over heating. Would 135c be considered stagnation that could damage the system or is it within normal parameters?

Do you have a max cylinder temperature of circa 70C configured?

If so this may have turned off the pump, thus causing the high temperature on the roof. You should check the max temperature rating for your cylinder. Other than that could it be a fualty pump(unlikely).

You didnt show the pump status in the chart (R1 ?). Also, worth knowing the system spec (# tubes & system etc)0 -

135 would be normal on most systems - I am always wary of allowing the pump to come on at 135 as if the pressure has fallen below 2 bars, the system will be in stagnation (and running the pump may cause issues). For that reason, I prefer to set the max temperature that the pump can run at to 130 instead of the default 140.I came home today to see that the panel had reached 135c, is this a problem as its only April and its over heating. Would 135c be considered stagnation that could damage the system or is it within normal parameters?

HOWEVER, I didn't think your system should go into stagnation. Your tubes have a valve that keeps the fluid at 90 or 95 degrees surely?0 -

Just noticed earlier in the thread that you have HP400 tubes from Kingspan. They should cut out at circa 95C and thus the max roof temp should'nt be much higher. IIRC the commercial HP400 tubes cut out at circa 135C. So you should confirm that you have the correct HP400 installed and if so it sounds like it could be a warranty issue.0

-

I have pump set to stop feeding the tank at 68c, the max temp setting on the panel is 130c I assume to protect the pump.

As far as I know Kingspan supply two types of tubes one that cuts out at 90c and another that cuts out at 135c so I assume I have the one set to a higher temp.

Assuming the tubes disengage at 135c the glycol in the manifold cools anyway? So when the bottom sensor on the tank drops below the set 68c the pump comes on and the tubes engage the manifold again 0

0 -

Why not increase the 68C? (There can be issues in hard water areas & check your cylinder specs)

see

http://www.seai.ie/Grants/GreenerHomes/Installers/Good_Practices_for_Equipment_GHS_Vol_5.pdf0 -

Why not increase the 68C? (There can be issues in hard water areas & check your cylinder specs)

see

http://www.seai.ie/Grants/GreenerHomes/Installers/Good_Practices_for_Equipment_GHS_Vol_5.pdf

Thanks for that link Oaklands, where I live in Swords the water is moderately hard so I'm not sure how hot I should set the temperature too. I might up it to 75c an see how I get on.

As far as I can see the tank has a max of 95c

What's the ideal setting?0 -

Advertisement

-

If you have a Kingspan stainless steel cyclinder, they seem to have a safety release set to 90C and I notice that they also have immersion cut offs at 85C.

However, when 'pushing/stressing' systems its best to get hard figures from certified installers/manufacturers. So why not send off an email to KS or your supplier's technical support.

Also, if you indeed have the higher temperature (commercial class??) HP400s you should also check that liquid/coolant/pipes/pumps are within spec & OK at these higher temperatures for when the system maxes out.0 -

I have a Gledhill Lite Solar tank installed and from what I can see it has a built in pressure release valve set at 95c, I have upped the storage temp from 68c to 78c so hope the pump will have no reason to cut out again as I'll monitor the situation on long sunny days (run a bath if necessary). When on holidays I plan to make the central heating pump circulate for an hour in the evenings without the boiler running, this should dissipate some heat from the tank.

I will contact Kingspan and check to see why I was supplied commercial tubes as I'd sooner see them cut off at 90c especially since the panel is over sized.0 -

Can I make a suggestion to you. You obviously have your immersion set to run at about 60 deg C. Scalding point is 45 / 46 so why not lower your immersion temperature ?

Not many people realize that this can be done. Unscrew the cap off where the electricity wire clamps on to the top of the tamk

and you will see the top of the immersion unit which will look like this below. You should see a simple thermostat which you can adjust with a screwdriver or coin.

So setting to between 45 - 50 will allow another 10 - 15 deg temp rise in a day before hitting your max. Hopefully you can set your max temp nearer to 90 - that's what I have mine set to. I have a Tribune tank.

Link again to my live data feed for anyone interested - https://cosm.com/feeds/714360 -

I got on to Kingspan today and their engineer said that I have the HP450 panel installed and that it shouldn't be a problem with maxing out at 135c. He said the glycol only degrades around 185c, this afternoon I ran the central heating pump to circulate cold water from the rads through the tank and effectively lowered the temp in the tank by 10c in about 15 mins and transferred some free heat to the rads and into the house. Kingspans engineer suggested that I could add a relay that would switch on the circulating pump when the tank reaches 70c and switch off again at 65c, but for now I'll monitor the situation manually.

Championc thanks for the suggestion about the immersion but I don't have one wired up nor has the central heating buffered the tank since about Monday. The 55c in the top of the tank was there from the day before. I just checked now and at 6.15pm the roof temp is at 78c and the tank has 63c top to bottom. If I hadn't of dumped some heat this afternoon I recon the system would have maxed out again.0 -

John T Carroll wrote: »Have just completed 1 full calender year of running. (see excel attachment)

The Panel (2 X F.Plate) output was 918 Kwh from a Roches Point Solar radiation of 945 Kwh. This output equals 239 Kwh/M2 of panel. Inputting my details to the DEAP S.Sheet comes up with 270 Kwh/M2. I know there is a view out there that this should be 350/400 Kwh/M2 but I have never been of this persuasion, reasonably accurate measurement of the harvested output is really the only objective way of really knowing what your system is producing. A friend of mine (Cork) who has the "normal" setup of 3 F.Plates X 300 Litre Cylinder harvested 1336 Kwh, this gives an almost identical performance of, 1336/5.76, 232 Kwh/M2.There was no output from my panels for 37 days this year which just goes to show what a dismal summer we had even though it didnt have a huge effect on the Solar Radiation.

What did surprise me was that when I inputted my details into the DEAP S.Sheet and assuming an E.Tube array of the same Aperture Area (3.84 M2) that it only gave an output of 310 Kwh/M2 which is only 14.8% greater than the theoretical output of 270 Kwh/M2 for the F.Plate. The T-Sol gives a better but still poor, in my opinion, approx 25% better performance for the E.Tube(s). I would have expected at least 50% better performance but again, the only way to go is to measure it!.

So, finally, to answer the query "are you all pleased with your solar panels for hot water heating", my reply is yes, and even though pay back time is very long, it was the best €2706 that I've spent in a very long time, from a personal satisfaction point of view.

My roof pitch is 30/33 Deg. due South.

Happy New Year to All "on the Boards". JTC

The Solar Output from my system for the first six months of 2013 was 511 Kwh v/vs 429 Kwh for the for the first six months of 2012 which is19% greater.

The Solar Radiation (Roches Point,Cork) for the same periods was 542 Kwh/M2 v/vs 508 Kwh/M2 which is 6.7% greater. JTC0 -

The Solar Output from my system for 2013 was 1017 Kwh v/vs 918 Kwh for the for 2012 which is 10.8% greater.John T Carroll wrote: »The Solar Output from my system for the first six months of 2013 was 511 Kwh v/vs 429 Kwh for the for the first six months of 2012 which is19% greater.

The Solar Radiation (Roches Point,Cork) for the same periods was 542 Kwh/M2 v/vs 508 Kwh/M2 which is 6.7% greater. JTC

The Solar Radiation (Roches Point,Cork) for the same periods was 1052 Kwh/M2 v/vs 945 Kwh/M2 which is 11.3% greater.

Once again, a Happy and Prosperous New year to everyone on Boards.ie. John

Should have added that there was no Solar Output for 55 days in 2013.0 -

John T Carroll wrote: »The Solar Output from my system for 2013 was 1017 Kwh v/vs 918 Kwh for the for 2012 which is 10.8% greater.

The Solar Radiation (Roches Point,Cork) for the same periods was 1052 Kwh/M2 v/vs 945 Kwh/M2 which is 11.3% greater.

Once again, a Happy and Prosperous New year to everyone on Boards.ie. John

Should have added that there was no Solar Output for 55 days in 2013.

"30 Tube" Evacuated Tube owners might find the attachment of some use.

One owner in Dublin yesterday had his calculated harvested output of 3.0 Kwh. The attachment calculates it at 2.5 Kwh or so, but thats OK as other factors such as local solar radiation levels etc all affect the theoretical calculation, this attachment is a pretty good guide as to whats happening with your evacuated tubes.0 -

John T Carroll wrote: »"30 Tube" Evacuated Tube owners might find the attachment of some use.

One owner in Dublin yesterday had his calculated harvested output of 3.0 Kwh. The attachment calculates it at 2.5 Kwh or so, but thats OK as other factors such as local solar radiation levels etc all affect the theoretical calculation, this attachment is a pretty good guide as to whats happening with your evacuated tubes.

Apoligies, made a mistake in that last Spreadsheet in that I hadnt included the solar hours. This has to be inputted as well because on two different days with exactly the same daily solar radiation then the Solar Array output can be completely different.

I have attached a corrected S.sheet and also added in a typical flat plate for comparison.

If anyone has saved the previous S.sheet then please delete or ignore it as it is incorrect and can be misleading.

I have actually compared the evacuated tube with a 2 Panel Flat Plate (my installation) which is the fairer comparison from an aperture area point of view so "3 panel" should have read "2 Panel". The calculations are correct. I dont want to post another "corrected" S.Sheet to avoid any more confusion.0 -

John T Carroll wrote: »The Solar Output from my system for the first six months of 2013 was 511 Kwh v/vs 429 Kwh for the for the first six months of 2012 which is19% greater.

The Solar Radiation (Roches Point,Cork) for the same periods was 542 Kwh/M2 v/vs 508 Kwh/M2 which is 6.7% greater. JTC

The Solar Output from my system for the first six months of 2014 was 519 Kwh.

The Solar Radiation (Roches Point,Cork) was 583 Kwh/M2.0 -

Advertisement

-

John T Carroll wrote: »The Solar Output from my system for 2013 was 1017 Kwh v/vs 918 Kwh for the for 2012 which is 10.8% greater.

The Solar Radiation (Roches Point,Cork) for the same periods was 1052 Kwh/M2 v/vs 945 Kwh/M2 which is 11.3% greater.

Once again, a Happy and Prosperous New year to everyone on Boards.ie. John

Should have added that there was no Solar Output for 55 days in 2013.

The Solar Output from my system for 2014 was 998 Kwh vs 1017 Kwh for 2013 which is 1.9% less.

The Solar Radiation (Roches Point,Cork) for the same periods was 1083 Kwh/M2 vs 1052 Kwh/M2 which is 2.9% greater.

There was no Solar Output from my system for 36 days in 2014.

Once again, a Happy and Prosperous New year to everyone on Boards.ie.0 -

John T Carroll wrote: »The Solar Output from my system for 2014 was 998 Kwh vs 1017 Kwh for 2013 which is 1.9% less.

The Solar Radiation (Roches Point,Cork) for the same periods was 1083 Kwh/M2 vs 1052 Kwh/M2 which is 2.9% greater.

There was no Solar Output from my system for 36 days in 2014.

Once again, a Happy and Prosperous New year to everyone on Boards.ie.

A Friend of mine, who has 3XF.Plates +300 Litre Cylinder (also in Cork) made 1263 Kwh in 2014 and 1234 Kwh in 2013.0 -

I think I have a problem with the Output calculation parameters because my system has recorded an annual output of 2329. Is this possible on my 30 Tube Kingspan connected to 180 Litre buffer0

-

Unlikely. These are the figures Kingspan use for DEAP. Probably conservative, as is the DEAP, and the output is constrained by the house size and assumed water consumption. I wonder if your flow rate is correct?0

-

I think I have a problem with the Output calculation parameters because my system has recorded an annual output of 2329. Is this possible on my 30 Tube Kingspan connected to 180 Litre buffer

I would suggest that the system would/should have made around 1100 to 1300 Kwh for 2014. Based on my F.Plate output I would have expected around 1100 Kwh had I installed a 30 E.Tube array.

The Steca Controller determines the heat quantity by using a combination of the flowrate and the Collector delta T between the collecter flow and return temperature.. The flowrate is obtained directly from a pulse generator, if fitted, or generically, by inputting the flowrate at the minimum and maximum allowable current pump speed settings and the controller then calculates the flowrate by interpolating between the two. I would suggest setting the pump on fixed speed at its current set minimum speed on a “good” solar day and by doing a few calculations as per my very first post, you can determine the actual heat quantity, compare this with the recorded heat quantity and then change the inputted flowrate at this minimum speed . Carry out the same routine at the current set maximum speed . It should be relatively easy to get an accurate estimation of the heat quantity as systems utilising variable speed mode spend long periods running at pretty low pump speeds.

There may be another complication in the calculation of your systems heat output, the system has two coils with an actuated valve to heat either the whole cylinder or to heat approx the upper 125 Litres (Top Loading), now if the collector return temperature probe is installed after the "T" where the top coil return and the bottom coil return are connected together then the return temperature will always be valid whichever loading stratagy is in use. However if the return temperature probe is installed in the return leg from the bottom buffer before the "T" then the controller will be looking at a dead leg temperature for the total duration of Top Loading which is the system "normally" in use. It might be worth looking at this probe location anf if surface mounted to the return pipework then it should be easy to locate it downstream of the "T". John0 -

John T Carroll wrote: »The Solar Output from my system for 2014 was 998 Kwh vs 1017 Kwh for 2013 which is 1.9% less.

The Solar Radiation (Roches Point,Cork) for the same periods was 1083 Kwh/M2 vs 1052 Kwh/M2 which is 2.9% greater.

There was no Solar Output from my system for 36 days in 2014.

Once again, a Happy and Prosperous New year to everyone on Boards.ie.

The Solar Output from my system for 2015 was 741 Kwh vs 998 Kwh for 2013 which is 26% less.

The Solar Radiation (Roches Point,Cork) for the same periods was 1027 Kwh/M2 vs 1083 Kwh/M2 which is 5.2% less.

There was no Solar Output from my system for 75 days in 2015.

One of the main reasons for the 26% reduction in output was that for various reasons my hot water demand was only around 73 LPD (45C) as against 100 LPD before. This resulted in the panels running much hotter resulting in a big fall off in efficiency of the Flat Plates and even though it was a very dull summer I rarely needed to supplement the solar for almost 4 months, I suppose this is fairly true of any system if not using alot of hot water!!.

Once again, a Happy and Prosperous New year to everyone on Boards.ie.0 -

Advertisement

-

John T Carroll wrote: »The Solar Output from my system for 2015 was 741 Kwh vs 998 Kwh for 2013 which is 26% less.

The Solar Radiation (Roches Point,Cork) for the same periods was 1027 Kwh/M2 vs 1083 Kwh/M2 which is 5.2% less.

There was no Solar Output from my system for 75 days in 2015.

One of the main reasons for the 26% reduction in output was that for various reasons my hot water demand was only around 73 LPD (45C) as against 100 LPD before. This resulted in the panels running much hotter resulting in a big fall off in efficiency of the Flat Plates and even though it was a very dull summer I rarely needed to supplement the solar for almost 4 months, I suppose this is fairly true of any system if not using alot of hot water!!.

Once again, a Happy and Prosperous New year to everyone on Boards.ie.

Interesting reading, thanks for that.

Apart from hot water, was the power generated used within the house?0 -

nice_guy80 wrote: »Interesting reading, thanks for that.

Apart from hot water, was the power generated used within the house?

Mine is Solar Thermal with a solar coil in the bottom of the hot water cylinder and not Solar PV.0 -

Dear John

I have been reading your posts with great interest. I am currently installing a 40 tube solar water heating system. I intend to monitor the system with a Raspberry Pi based system from the OpenEnergy Monitor Project(https://openenergymonitor.org/emon/modules/emonpi). This will enable me to take measurements from 6 sensors.

I am using this project to get an understanding of the Raspberry Pi and also develop some basic maths to show how much the solar panels are returning me and also enable me to perhaps change some behaviours in my house.

I was wondering if you could provide or point to some good explanations of the maths behind the types of dashboards that you are providing.

Thanks in advance.0 -

Dear John

I have been reading your posts with great interest. I am currently installing a 40 tube solar water heating system. I intend to monitor the system with a Raspberry Pi based system from the OpenEnergy Monitor Project(https://openenergymonitor.org/emon/modules/emonpi). This will enable me to take measurements from 6 sensors.

I am using this project to get an understanding of the Raspberry Pi and also develop some basic maths to show how much the solar panels are returning me and also enable me to perhaps change some behaviours in my house.

I was wondering if you could provide or point to some good explanations of the maths behind the types of dashboards that you are providing.

Thanks in advance.

No problem, would you please tell me the make/model of your solar controller as its very important that this has a facility for calculating the energy harvested. Go to my very first post (20/9/2012) and there is a explanation there of how I set up my system, there are various methods of gathering this info but it is very dependant on the type of controller fitted.0 -

John, thank you. The controller in question is a DeltaSol BS/2. I think is a re-badged (for Joule) version of a Resol controller.

http://www.resol.de/Produktdokumente/48005952_DeltaSol_BS2_V2.monen.pdf

The evacuated tubes are Joule Acapella. See page 57 of http://www.jouleuk.co.uk/wp-content/uploads/2015/11/Cyclone-Stainless-Solar-Heat-Pump-Brochure-2016.pdf for specifications

I have two twenty tube racks feeding a 300L Cylinder.

My roof is approximately 185 degs south facing.0 -

Advertisement

Advertisement